7 Important Types of Quality Management System

-

By Afra Noorain

By Afra Noorain - Published on Jun 6 2024

Table of Contents

Introduction to Quality Management Systems

A QMS is a guideline, a set of procedures, and practices adopted by an organization according to achieve consistent quality. A QMS focuses on meeting and exceeding customer expectations by identifying their needs and ensuring products or services consistently address them. QMS establishes clear processes for all activities carried out within the setup of that organization, ensuring consistency and minimum possible errors. It is exposed to process improvement and helps in the evaluation and improvement of processes intending to attain a higher level of quality. This way, it encourages making data-driven decisions with more informed choices.

Implementation will be a good practice with full commitment to the leadership and active participation of all levels of an organization. In the present competitive business scenario, no organization can expect to succeed and sustain only its goods and services; rather, it has to maintain a high standard. Types of Quality Management Systems assist organizations in coordinating and directing their activities to achieve objectives through meeting consumer and regulatory requirements and raising efficiency and effectiveness continuously.

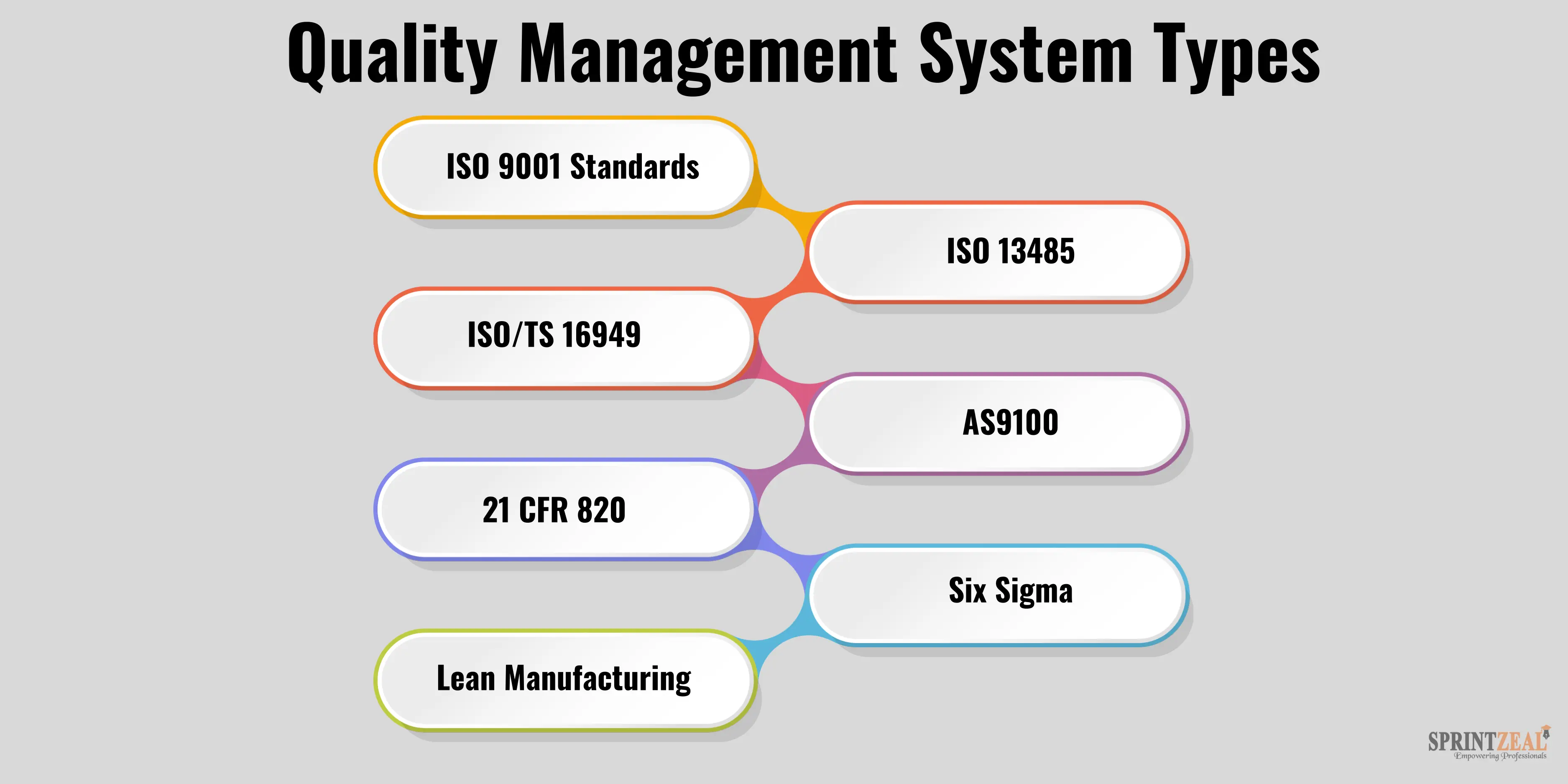

Most Common Types of Quality Management Systems

There are several popular Types of Quality Management Frameworks, each with different strengths and focus. Some of the most common are listed below:

- ISO 9001 Standards

The ISO 9001 standards are among some of the most recognized and applied Quality Management Frameworks in the world. According to the International Organization for Standardization, a series of standards aims at outlining a group of principles that ensure an organized approach to managing organizational procedures and the delivery of products meeting the customer's needs.

Improve your skills and boost your career by enrolling in our ISO 9001 training programs. Check out the available courses and choose the one that fits your needs.

ISO 9001 Foundation - Learn the basics of implementing and managing a Quality Management System (QMS) and get an overview of ISO 9001 requirements.

ISO 9001 Lead Implementer - Gain the skills to set up, run, maintain, and continually improve a QMS according to ISO 9001 standards.

ISO 9001 Lead Auditor - Learn how to audit a QMS against ISO 9001 standards, following the guidelines and requirements of ISO 19011 and ISO 17021-1.

Key Features

It is focused on customer satisfaction and continuous improvement.

It provides a structure for the identification and management of risks.

Involves documented processes across all critical areas of business.

ISO 9001 is a certificate of an organization's ability to provide products and services that meet the requirements of customers and regulatory bodies consistently to ensure the maximum level of customer satisfaction.

- ISO 13485

ISO 13485 has been developed for the medical device industry, structured around the base of ISO 9001 with added requirements that are appended to take care of the design, manufacture, and servicing of medical devices. This standard is important in ascertaining the safety and effectiveness of medical devices.

Learn about Medical Devices Quality Management Systems with our Sprintzeal’s ISO 13485 training programs. Find the course that fits your needs below:

ISO 13485 Foundation - Get to know the best practices for Medical Devices Quality Management Systems (MDQMS) based on ISO 13485.

ISO 13485 Lead Implementer - Become skilled in implementing and managing MDQMS according to ISO 13485 standards.

ISO 13485 Lead Auditor - Learn how to audit MDQMS based on ISO 13485 standards.

Key Features

Works on regulatory needs and risk management.

Requires a systematic approach to the medical device lifecycle.

It emphasizes that production must be effective and post-market surveillance is to be sustained.

ISO 13485 enables any manufacturer to be sure that products are designed and maintained with due regard for the needs of both the customer and the obligations.

- ISO/TS 16949

ISO/TS 16949 refers to the worldwide technical specification and quality management standard applied by the automotive industry. It unites the numerous assessment and certification schemes in the international automotive supply chain.

Key Features

Is fully integrated into the ISO 9001 standards.

Focused on preventing defects, reduction of variation, and waste.

Emphasizes continuous improvement.

ISO/TS 16949 certification ensures that automobile manufacturers and their suppliers meet uniform quality standards throughout the industry.

- AS9100

AS9100 is a widely adopted, de facto, and standardized QMS in the aerospace business. It includes all of the ISO 9001 elements and augments them with some aerospace specifics that embrace safety, reliability, and regulatory compliance.

Key Features

It has very strict requirements for product traceability and documentation.

It focuses on risk management and mitigation.

Requires a great deal of attention to regulatory and customer requirements.

Overall, AS9100 certification should be able to meet a high-level quality appropriate for a safety-critical aerospace component and system.

- 21 CFR

Quality system regulation, as dictated by the Food and Drug Administration, for medical devices in the United States is found within 21 CFR 820. These drive current good manufacturing practices requirements for manufacturers of medical devices.

KeyFeatures

Full documentation and record-keeping shall be required.

Focus on design control and validation.

Emphasizes risk management within the product life cycle.

Manufacturers have to comply with 21 CFR 820 to sell their medical devices in the US, which is a criterion for products to be safe and effective.

- Six Sigma

Six Sigma is a data-driven methodology and an approach toward defect elimination in any kind of process. Though not a definition in QMS standards, it is usually incorporated in QMS frameworks to enhance quality and efficiency.

Key Features:

Uses statistical techniques to infer and remove causes of defects.

Focuses on process improvement and reduction of variability.

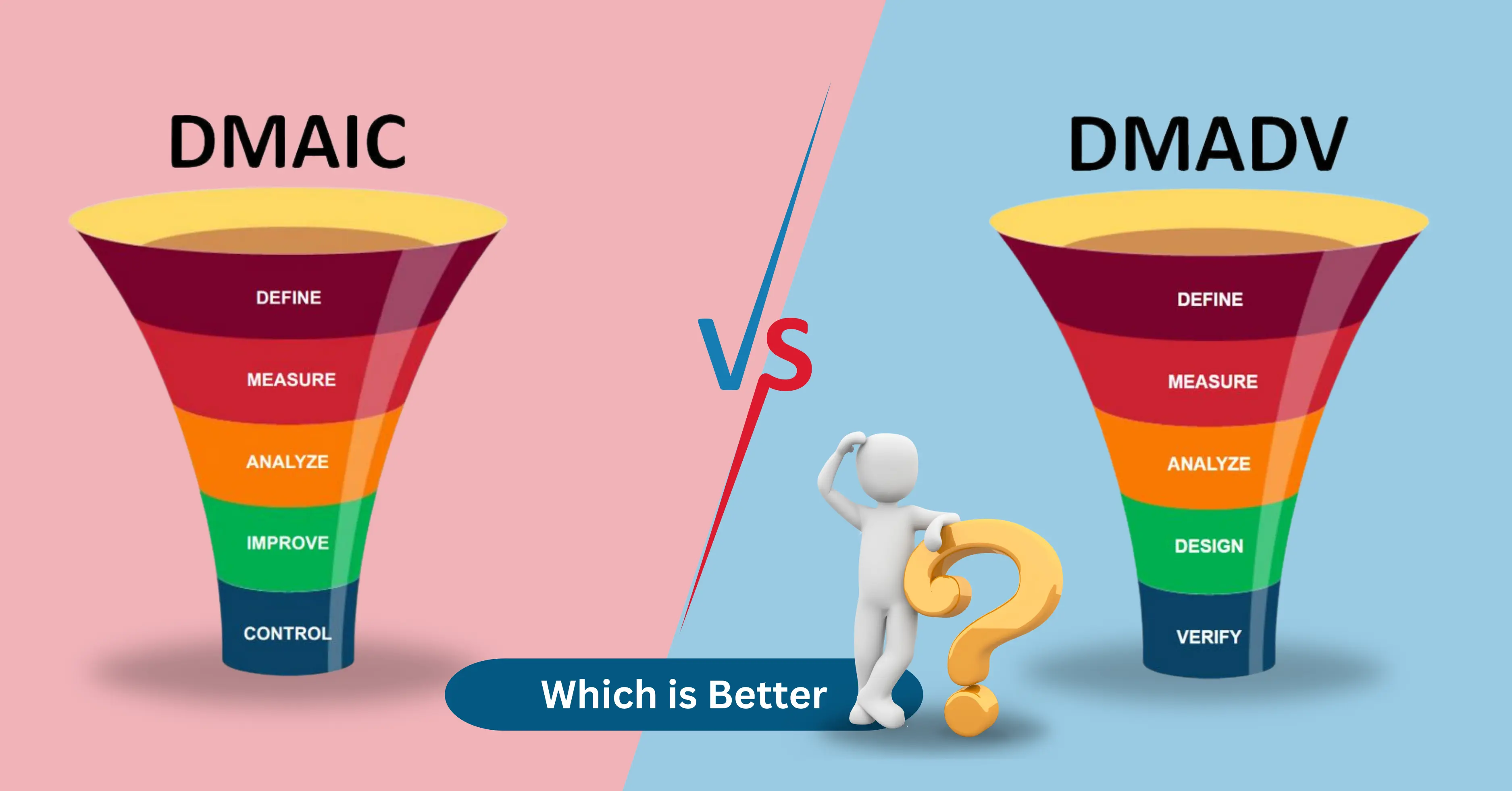

It uses a structured DMAIC (Define, Measure, Analyze, Improve, Control) process.

Six Sigma focuses on achieving an almost perfect defect rate; therefore, it considerably boosts the quality of goods and the satisfaction of customers with the products.

- Lean Manufacturing

Lean Manufacturing, another methodology, if not a standard QMS, most often surfaces in interfacing with any of these QMS frameworks. Lean focuses on removing waste without losing productivity.

Key Features:

Highlights added value to the customer.

Focuses on streamlining processes and eliminating non-value-added activities.

It uses tools like 5S, Kaizen, and Value Stream Mapping.

Lean Manufacturing enables the organization to be more effective and cut costs, briefly improving global product quality.

Why Implement a QMS?

There are several benefits to implementing QMS other than the quality of the product: Key Benefits of Implementing the Quality Management System -

Improved customer satisfaction due to consistent quality.

- Cuts costs through streamlined processes and improved efficiency.

- It increases productivity by simplifying workflows and makes employees more productive.

- Better risk management is improved due to detecting and mitigating potential issues.

- Provides greater competitive advantage through the reputation for consistent quality.

- Enhances compliance with industry regulations and standards.

Conclusion

Understanding the various quality management systems will help in the better practice of quality management within an organization. From ISO 9001 standards to 21 CFR 820 risk management, the systems come with tailored benefits for the respective industries and their needs. Together with appropriate Types of Quality Management Systems, it aids organizations in conformity, increasing their operational efficiency while providing customers with the best quality products and services. Such a QMS is robust by standard-based systems like ISO 13485, and AS 9100, and methodologies like Six Sigma, and Lean Manufacturing, which act as strategic investments for the long run in the success and competitive advantage of a company.

Embark on your path to professional growth with Sprintzeal's extensive range of Certified ISO Training courses. Whether you are new to Quality Management Systems or looking to enhance your expertise, we have a course tailored to your needs. Start your learning journey today and gain valuable skills to advance your career!

For more information and to discuss the best course for you, chat with our course expert now. Subscribe to our newsletter, and let us help you take the next step in your professional development!

Subscribe to our Newsletters

Popular Programs

Trending Now

Top Career benefits of Lean Six Sigma Green Belt

ArticleLean methodology, Six Sigma methodology and Lean Six Sigma Explained

ArticleSix Sigma Black Belt Certification – Value and Career Benefits in 2024

ArticlePareto Chart in Six Sigma - Explained

ArticleSix Sigma Certification Guide - A Professional's Guide

ArticleQuality Control Explained – Six Sigma

ArticleQuality Assurance in Six Sigma Explained

ArticleQuality Assurance vs Quality Control

ArticleTotal Quality Management - A Complete Guide for Beginners

ArticleSix Sigma Certification – Everything you Need to Know About Getting Certified

ArticleLean Six Sigma on Resume for Rewarding Career Benefits

ArticleSix Sigma Yellow Belt Certification - Six Sigma for Beginners

ArticleQuality Manager Interview Questions and Answers 2024(UPDATED)

ArticleService Delivery Manager Interview Questions and Answers (With Examples)

ArticleSix Sigma Interview Questions and Answers 2024

ArticleA Supply Chain Management Guide to Mastering Logistics End to End

ArticleSenior Quality Manager Interview Questions and Answers 2024

ArticleTop 30 Quality Analyst Interview Questions and Answers 2024

ArticleFinancial Analyst Interview Questions and Answers 2024

ArticleRisk Manager Interview Questions and Answers 2024

ArticleCompliance Manager Interview Questions and Answers 2024

ArticleOperation Manager Interview Questions and Answers

ArticleHow to Become a Quality Manager - Career, Job Scope and Certifications

ArticleHow to become a Quality Analyst

ArticleSix Sigma Certifications - Reasons Why you Should Get Them

ArticleTop Qualities of a Good Manager and a Leader

ArticleLearn about Statistical Process Control (SPC) and its top applications

ArticleCost of Poor Quality - A Detailed Guide

ArticleImplementing 5S Methodology for Better Work Efficiency

ArticleWhat Is Lean Management?

ArticleBest Six Sigma Books in 2024

ArticleLeadership vs Management - The Ultimate Guide

ArticleQuality Assurance Plan - Six Steps To Quality Assurance Plan

ArticleOperational Planning Creation, Key Elements and its Benefits

ArticleA Complete Guide to Product Life Cycle Stages 2024

ArticleWhat Is Lean Manufacturing?- An Overview

ArticleThe Lean Continuous Improvement Model: A Comprehensive Guide

ArticleDMAIC vs. DMADV: Key Differences and Choosing the Right Six Sigma Methodology

ArticleA Deep Dive into the Power of Lean Continuous Improvement Process

ArticleIntroduction to Lean Manufacturing- Definitions, Framework, and More

ArticleLean Continuous Improvement Methods for Business Excellence

ArticleUnderstanding the Key Principles of Lean Manufacturing

ArticleSecret to Unlock Organizational Excellence: Stages of Continuous Improvement

ArticleLean Continuous Improvement: A Detailed Guide to Mastering Organizational Quality

ArticleLean Waste Management: The Ultimate Guide 2023

ArticleA Deep Dive into Lean Continuous Improvement Tools

Article8 Wastes of Lean - Strategies for Identification and Elimination

Article5 Lean Continuous Improvement Principles to Supercharge Your Operations

ArticleThe Ultimate Guide to Lean Manufacturing

ArticleUnderstanding Lean Manufacturing's Pros and Cons

ArticleLean Waste Reduction Strategies: Boost Efficiency and Cut Costs

ArticleTop 10 Lean Manufacturing Tools for Optimal Productivity

ArticleBeyond the Basics: Benefits of Lean Continuous Improvement

ArticleWhat are Quality Standards? | A Guide to ISO Standards

ArticleISO 9001 Standard: Benefits and Certification

ArticleA Comprehensive Guide to Quality Management Systems

ArticleCategories

- Agile Management 59

- AI and Machine Learning 29

- Big Data 52

- Business Management 25

- Cloud Computing 37

- Digital Marketing 51

- Information Security 1

- IT Hardware and Networking 13

- IT Security 79

- IT Service Management 28

- Microsoft Program 2

- Other 29

- Programming Language 29

- Project Management 124

- Quality Management 57

- Risk Management 2

- Workplace Skill Building 1

Trending Posts

How to Become a Quality Manager - Career, Job Scope and Certifications

Last updated on Dec 18 2023

Beyond the Basics: Benefits of Lean Continuous Improvement

Last updated on Jan 16 2024

Six Sigma Certification – Everything you Need to Know About Getting Certified

Last updated on Nov 8 2023

Top Qualities of a Good Manager and a Leader

Last updated on Aug 11 2022

What are Quality Standards? | A Guide to ISO Standards

Last updated on Jun 4 2024

DMAIC vs. DMADV: Key Differences and Choosing the Right Six Sigma Methodology

Last updated on Nov 10 2023